*Dr. Huang, the president of Sunrise Instruments (SRI), was recently interviewed by Robot Online (China) in the SRI new Shanghai headquarter. The following article is a translation of the article by Robot Online.

Introduction: It is half a month before the official launch of the SRI-KUKA Intelligent Grinding Laboratory and the SRI-iTest Innovation Laboratory, we met York Huang, the president and founder of Sunrise Instruments in SRI Shanghai headquarter.” Compared with the title of “president”, I prefer being called Dr. Huang.” It might be that the title better explains Dr. Huang’s technical background, as well as he and his team’s persistence in product innovation.

Humble but Excellent performance

Unlike many outstanding companies in the industry, SRI seems to be very low-key. For over ten years before 2007, Dr. Huang has been engaged in the design and development of six-axis force/torque sensors in the United States. He is the chief engineer of FTSS (now Humanetics ATD) which is the global leader in automotive collision dummies. Sensors designed by Dr. Huang can be found in most automobile collision laboratories in the world. In 2007, Dr. Huang went to China and founded SRI, becoming the only company in China that has the capacity to produce multi-axis force sensors for car crash dummies.At the same time, the multi-axis force sensor was introduced into the field of automobile durability testing. SRI started the journey in the automobile industry with cooperation with SAIC, Volkswagen and other car companies.

By 2010, the robotics industry had entered a stage of rapid development. Two years later, SRI became ABB’s global supplier. Dr. Huang developed a six-axis force sensor specifically for ABB intelligent robots. The sensor is currently being used in many countries around the world. Besides ABB, SRI also cooperated with a few other global well-known companies in the robotic industry. After the development of collaborative robots and medical robots, the joints of the robots began to be equipped with torque sensors. SRI’s new partner is Medtronic, the world’s largest medical equipment company. SRI sensors were integrated in Medtronic abdominal surgery robots. This is also a sign that SRI products meet the high requirements of medical equipment production.

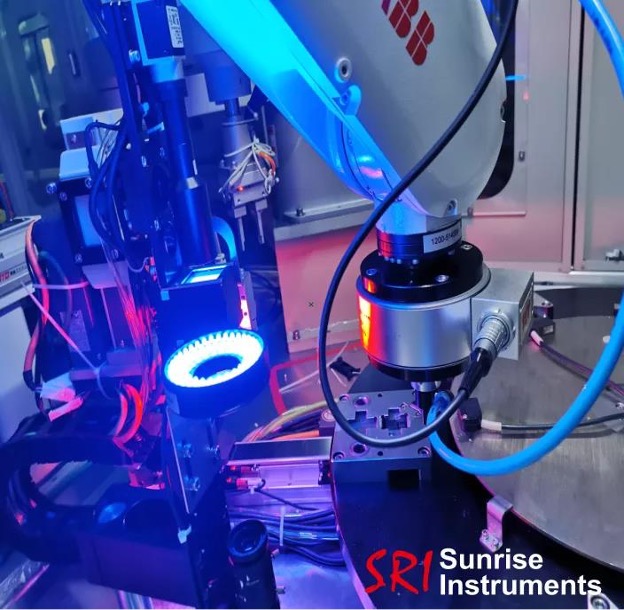

*An SRI six axis sensor designed for ABB robot.

A company that has cooperated with many well-known companies in the industry, does not, however, have much relevant publicity on their own platform like many others do. SRI focuses more on the product performance than the marketing strategies. There is quite a temperament of "sweeping things away, hiding merit and fame".

Innovation based on demands

After some exploration in the field of robotics, Dr. Huang observed that promising force sensors account for a small proportion in the field of industrial robotics. To understand why force control was not fully applied in the robotic grinding field, SRI and Yaskawa reached a cooperation and finally found that robots using force sensors alone cannot satisfy the industry demand. In 2014, SRI iGrinder intelligent floating grinding head was born. The product integrates force control, position transmission control and pneumatic servo technology to solve industrial problems.

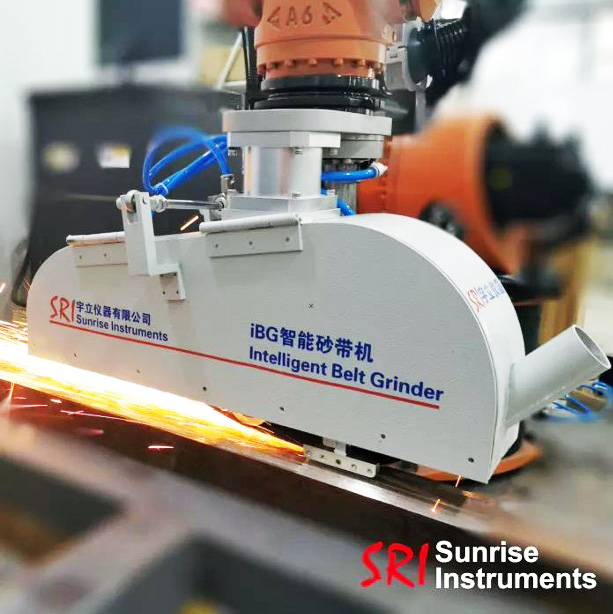

*An SRI Heavy-duty iGrinder is grinding a metal part.

Perhaps out of confidence in technology, a sense of accomplishment in facing difficulties, but mostly because of the urgent need to solve industrial problems, Dr. Huang focused on tackle the most difficult problem recognized in the industrial field---Grinding, the iGrinder intelligent floating grinding head has become one of SRI's "Master Products."

Dr. Huang mentioned: "So far, SRI has more than 300 products. Our product design, R&D, and production are all refined from user specific need and applications, not what is hot or being offered in the market."

A typical example is the foot bionic sensor developed by SRI, which can help stroke patients gain "sensation" and stand up again to walk on their own. To achieve this goal, it is necessary to ensure that the sensor accurately transmits information and quickly responds to subtle changes, but also to ensure that the product is thin and light to reduce the burden on patients. Refining the goal from this demand, SRI finally developed a force sensor with a thickness of only 9mm, which is currently the thinnest six-axis force sensor in the global business world. SRI sensors are well acclaimed in the research and application of intelligent prosthetics in the United States.

*SRI Intelligent Belt Grinder

From the "old" road to a new journey

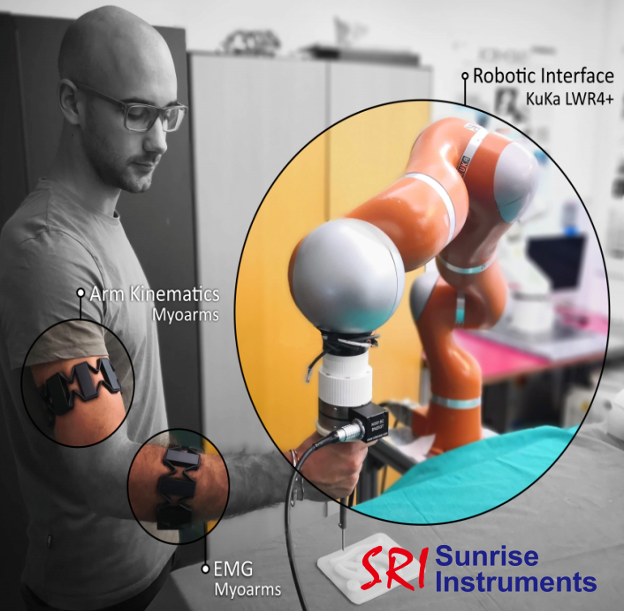

In 2018, KUKA became a cooperative customer of SRI. On Aril 28, 2021, SRI will launch the "SRI-KUKA Intelligent Polishing Laboratory" in Shanghai, dedicated to overcoming industrial problems in the polishing field and solving practical problems for end users.

At present, intelligent sensors have entered a expansion period and have begun development in consumer electronics, medical electronics, network communications and other fields. SRI is not limited to the industrial field but gradually expanding into other areas. Dr. Huang said that to implement applications, big data information is needed. Therefore, the sensor field also needs to establish a platform, a multi-sensor, multi-device fusion platform. Combining them requires cloud management and intelligent control. This is what SRI is currently doing.

onic sensor developed by SRI, which can help stroke patients gain "sensation" and stand up again to walk on their own. To achieve this goal, it is necessary to ensure that the sensor accurately transmits information and quickly responds to subtle changes, but also to ensure that the product is thin and light to reduce the burden on patients. Refining the goal from this demand, SRI finally developed a force sensor with a thickness of only 9mm, which is currently the thinnest six-axis force sensor in the global business world. SRI sensors are well acclaimed in the research and application of intelligent prosthetics in the United States.

*SRI sensors designed for Kuka LWR4+

Future goals for the SRI are made by Dr. Huang after understanding the market. He found that it takes hundreds of thousands of costs for end users in the grinding/polishing industry to truly realize automation, which is very difficult for small and medium-sized enterprises. Therefore, SRI hopes to combine the robot with other equipment, not only have hardware facilities, but also simplify the software, so as to save costs and enable the robot to truly realize the application.

In the familiar automotive field, SRI has also been advancing. Dr. Huang said that traditional auto parts testing is almost "monopolized" by a few companies with a long history. In the robotic testing area, however, SRI has been able to claim a place. On April 28, SRI will also launch the "SRI-iTest Innovation Laboratory". iTest is a joint studio for testing new technology development across companies within the SAIC Group, dedicated to the development of the new four modernizations test technology and independent research and development of testing. iTest will create a smart test system of SAIC and improve the overall level of testing in the automotive industry. The core team includes SAIC Passenger Cars, SAIC Volkswagen, Shanghai Automotive Inspection, Yanfeng Trim, SAIC Hongyan and other test technology research and development teams. With the well-developed software and hardware and the experience of past successful experience, SRI and SAIC have established this innovation laboratory to push the cooperation of autonomous driving test forward. In this new field, the market is not crowded and has a lot of room for development.

*SRI sensors in automotive crash test and durability test

"A robot can only be a machine without sensors", Dr. Huang’ confidence in sensor applications and technology is beyond words, supported by excellent products and successful applications. Shanghai is a hot land, which will bring more opportunities and vitality. In the future, perhaps SRI will remain low-key, but the strength and quality of the products will make the enterprise a long-standing company.